Industrial risks

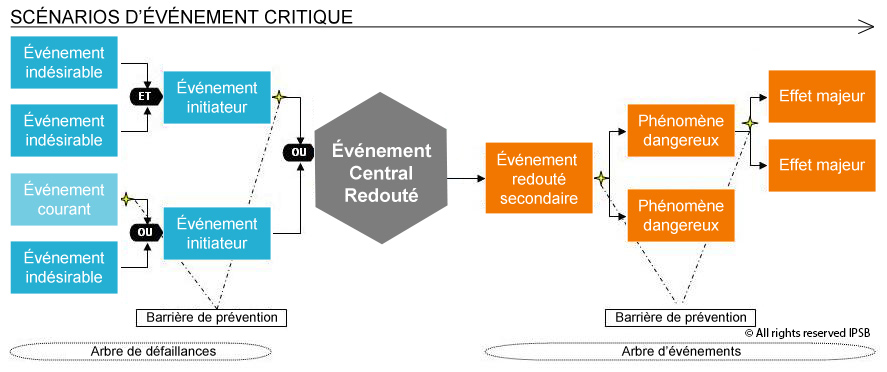

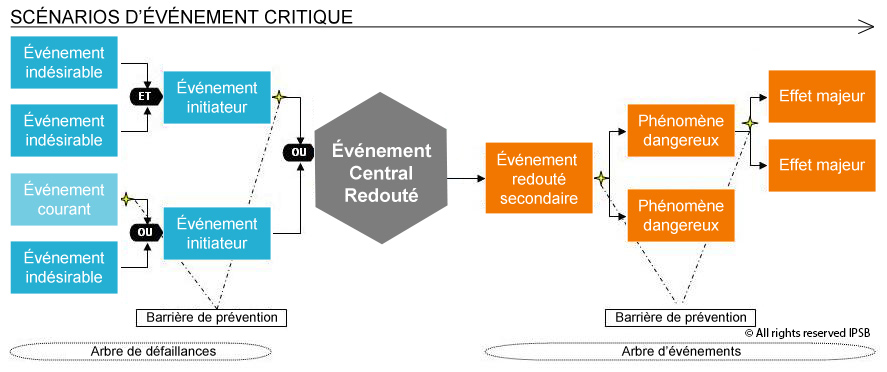

IPSB has the technical and regulatory expertise to assist you in controlling the industrial risks associated with your projects. We carry out risk analyses according to the most appropriate methods (FMECA, HAZOP, Bow-Tie, etc.) and model the consequences of accident scenario using recognized tools.

The purpose of risk analysis is to evaluate methodically and as exhaustively as possible the risks related to the operation of an industrial installation regarding the safety of people, the protection of the environment and the integrity of the production unit.

IPSB will accompany you in carrying out your risk analyses by:

- Taking inventory of industrial accidentology on similar processes and identifying the dangers related to the products implemented

- Selecting the method (or combination of methods) most appropriate to the issues you are facing

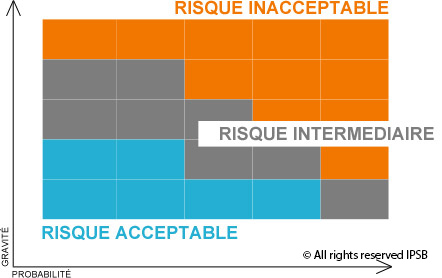

- Defining a reference framework in terms of frequency of occurrence, seriousness, criticality matrix and confidence level by safety barrier type

- Determining the functional organization of your units and the different phases of functioning

- Implementing the appropriate method by leading working group sessions

- Proposing complementary safety measures to reduce risk to an acceptable level

- Drafting the summary of the risk study and of the action plan by order of priority

With their mastery of different analytical methods (FMECA, HAZOP, Bow-Tie, Failure Tree, etc.) and with knowledge of your industry and its processes and products, our engineers will assist you in identifying major accident scenarios and in choosing the appropriate safety measures.

Additionally, in order to evaluate the consequences of accident phenomena (fire, thermal explosion, torch fire, etc.), IPSB can model thermal and pressure effect areas using 2D and 3D software (based on the French petroleum industry danger study methodology guide recognized by the French authorities) and/or empirical formulations.

A project ? Contact us !