Energy audits

The construction of new power plants (thermal or nuclear) will not be sufficient to meet demand and compensate for the reduction of fossil fuel energy. To solve this dilemma, one alternative is to implement energy efficiency solutions that allow for doing more with fewer resources.

Our energy audit activities meet the expectations of our clients by reducing energy costs and consequently decreasing green-house gas emissions.

As a first step, we record on site process functioning points and calculate the plant mass and energy balance. This balance constitutes a photograph of the production line and our experts use it to carry out a quantitative analysis of the plant’s weak points.

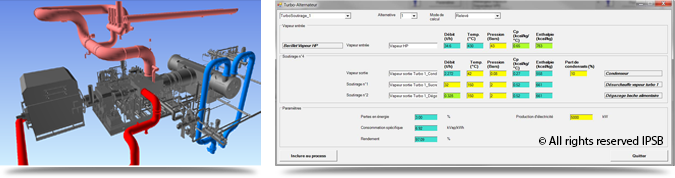

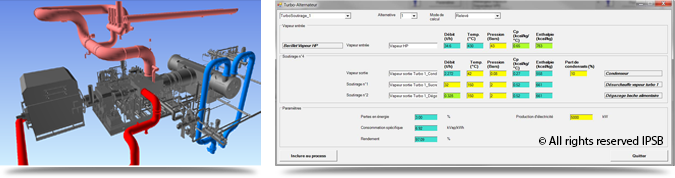

To make such assessments, we have developed in-house specific software to model the main unit operations and to simulate the functioning of a fully-equipped production plant, integrating the main flows and the recycling of secondary flows.

Analysis of these assessments allows our experts to:

- Identify and prioritize improvement opportunities in order to optimize energy consumption (energy coupling and flow recycling).

- Propose appropriate technical solutions

- Quantify expected results and evaluate the cost of the technical solutions proposed to determine investment payback time